DandySolutions

Thoughts and Ideas from Andy M

I have been creating things since

high school. This website will

eventually have as many of those ideas as I can document.

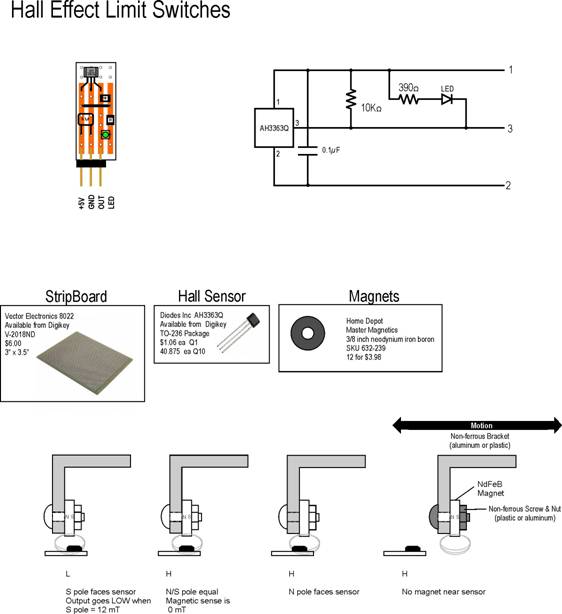

Hall Effect Switches

I had a project that needed

limit switches that were non-contact and could be water/solvent proof. Optical was a possibility but I was worried

about fluid spray causing false readings.

I had previously used Hall

Effect sensors in a project but those were analog, producing a voltage

proportional to distance. That would

work but it would require measuring a multitude of voltages. Having previous experience with voltage

sensing I wanted to see what else I could dream up in the digital world.

Looking

through the available Hall Sensors, there was a class of sensor that output a

digital signal, send 1 for one magnetic field and 0 for another field

level. Those sensors came in two general

types. Type 1 was referred to as bipolar

latch. It’s output went high (logic 1)

when a north pole of a magnet approaches and low (logic 0) when a south pole of

a magnet approaches. If no magnetic

field is present, the device remains in the state (1 or 0) it was last set to.

Type

2 was referred to as a unipolar switch. If

no magnetic field is present, the output will be high (logic 1). As a south pole approaches, when close enough

the output will go low (logic 0).

Bringing a north pole to the switch causes it to remain in the high

(logic 1) state, the same as no magnetic field.

If

a magnet passes sideways near the switch with the north and south poles aligned

along the axis of motion and the north pole approaches first, the switch will

be high until the center of the magnet passes the switch. Before it passes by, the north pole will

cause a high output. As it passes and

the south pole faces the device, the output will go low. The choice of the Type 2 sensor is vital

because it establishes the output state when the magnet is far away from the

switch.

This

sensor will also work if the south magnetic pole approaches first but the

accuracy will ne much less. This is

because the sensor is measuring the strength of the magnet as it

approaches. The strength of the field

will increase as the magnet approaches.

As the magnet moves away, the sensor will eventually drop below its hold

field and go high but the activate point and the release point will be fairly

far apart.

If

the magnet approaches north pole first, as the body of the magnet passes the

sensor, the field will reverse (north to south) just as the centerline passes

giving a very sharp switch point. Going

back the other way gives an equally sharp change from south back to north.

I

make the sensor boards using stripboard.

I cut a piece of the stripboad with 4 copper traces on it. I put an led on the board so that I can

visually comfirm proper operation without consulting the monitoring

equipment. I use the small square pin

connectors for connection and the choice of ground in the middle keeps damage

from occurring if the connector is installed reversed. It won’t operate but reversing the connector

will fix the issue with no blown parts.

If

you have never used stripboard, look online for information about using

it. It is very useful to have a 7/64

inch drill bit in a small hand chuck.

You need this to ‘cut’ the traces where required. An electric drill is too hard to control and

often results in a hole through the board.

Since

these sensors are magnetic, and shielding like plastic tubing will cause no

problems. Some sensing works through

thin wall aluminum tubing if you need that much shielding. Also note that the neodymium-iron-boron

magnets are MOSTLY iron and thus will rust.

The factory plates them with nickel to prevent this but I have found

that the nickel plating is porous and rust through it possible. If you expect the magnet to be water

wet, coat it in a waterproof

coating. Epoxy or silicone sealant if

repel water and have no effect on the magnet field.

Diagram

2

The DS18B20

Temperature Sensor and Fahrenheit

I

have used several different temperature sensors in the past, like the LM76 and

others so when the DS18B20 came out using a one-wire interface, I immediately

bought some to test. Writing the code

was fairly easy until I wanted the result to be in °F. If you are working in a language with

floating point math, it is easy to follow the old conversion:

°F

= (°C * 5 / 9)+32

The

problem I had was the system I was creating was based upon an Atmel AVR

microcontroller and the entire program storage space was less than the size of

the floating point libraries available.

So I tackled the problem of doing this conversion with only integer

arithmetic and an 8 bit CPU.

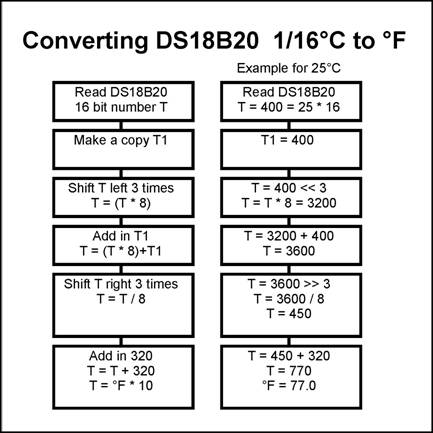

First

thing was that the DS18B20 produced temperatures in 1/16 degrees C. That roughly corresponds to 1/10 degree F so

a conversion from 16ths C to 10ths F was the solution. Since the DS18B20 produced 1/16ths C and

those 16 16ths corresponded to 18 10ths degree F I needed a ratio conversion of

16:18.

16:18

can be reduced to 8:9 (divide by 2) so the conversion needed was to multiply

the DS18B20 output value by 9 and then divide by 8. Multiply by 9 is easy: multiply by 8 (three shifts left) and then

add in the original value (*9 ≡ *8

+ *1) and then dividing by 8 is easy, three shifts right. Oh, and then add in the constant 32 which is

320 because we are counting in 1/10ths F.